Manufacturing

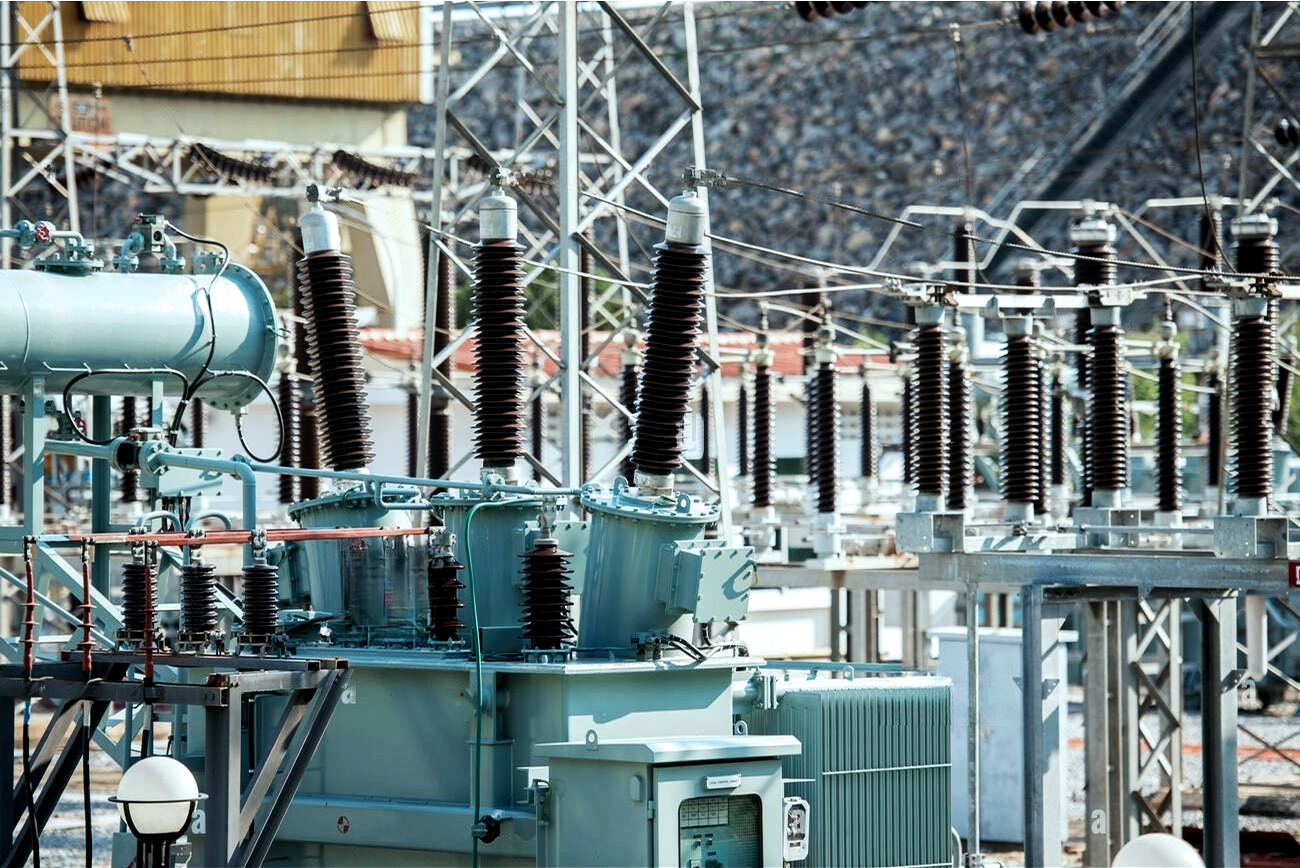

Our manufacturing process begins with meticulous design and engineering. Our expert team formulates detailed plans based on specific requirements, including voltage, power capacity, and application. We focus on core material selection, winding arrangements, and advanced cooling systems, ensuring every aspect meets the highest standards of precision and innovation